| 올림푸스 Photo&TalK |

|

http://techon.nikkeibp.co.jp/atclen/news_en/15mk/122000258/

http://techon.nikkeibp.co.jp/atclen/news_en/15mk/122000258/

Olympus Integrates Visible, Infrared Image Sensors

올림푸스가 가시광선 이미지 센서와 적외선 이미지 센서를 통합하다

Tetsuo Nozawa, Dec 21, 2015

Olympus Corp developed a device by integrating a color visible-light image sensor and a near-infrared image sensor.

올림푸스 사는 가시광선 대역의 이미지 센서와 근적외선 영역의 이미지 센서를 통합한 장치를 개발하였다.

Olympus used a lamination technique to stack them. The company made this announcement Dec 9, 2015, at IEDM 2015 (thesis number 30.1).

올림푸스는 적층 기술을 이용하여 두 반도체를 겹쳐 쌓았다. 이 제품은 12월 9일 IEDM 2015(논문번호 30.1)에 공개되었다.

The device is expected to be used for (1) medical purposes such as examination of veins under skin with a near-infrared sensor and pathological examination of living tissues with a fluorescent material, (2) security applications such as vein authentication and (3) distance measurement based on the time difference between irradiation and reception of infrared light.

이 장치는 (1) 근적외선 센서를 이용한 피하 혈관의 시험이나 형광물질을 이용한 생체조직의 병리학적 시험 등의 의료적 목적과 (2) 혈관인식 등의 보안 목적 (3) 적외선의 방사-수신 시간차를 이용한 거리측정 등에 사용될 수 있을 것으로 보인다.

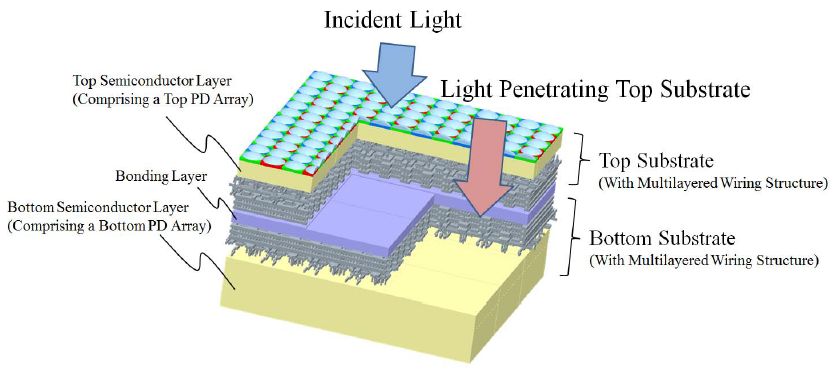

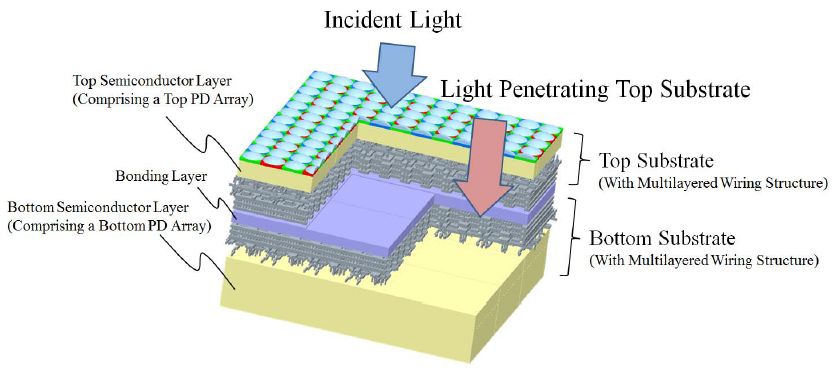

The laminated image sensor is made by combining (1) an image sensor equipped with an RGB color filter for visible light (top layer) and (2) a near-infrared image sensor (bottom layer). Each layer functions as an independent sensor and independently outputs video signals.

적층 이미지 센서는 (1) RGB 컬러필터를 갖춘 가시광선 대역 이미지 센서(상층부)와 (2) 근적외선 이미지 센서(하층부)로 구성된다. 두 면은 서로 독립적으로 작동하며 비디오 신호 또한 독립적으로 출력한다.

The visible-light image sensor is a backside-illuminated type, and its light-receiving layer (made of semiconductor) is as thin as 3μm. Each pixel measures 3.8 x 3.8μm, and the number of pixels is 4,224 x 240.

가시광선 대역은 이면조사(BSI) 형식이며, 반도체로 제작된 감광영역의 두께는 3마이크로 정도의 두께이다. 각 픽셀은 3.8x3.8 마이크로미터이며, 센서의 픽셀 숫자는 4,224 x 240 픽셀이다. (역주 : 3.8마이크로미터의 픽셀피치는 1600만 화소 마이크로포서드 센서 정도입니다.)

One of the concerns about such a laminated type is that infrared light becomes a noise for visible-light images. In many cases, conventional visible-light image sensors remove the influence of infrared light on visible-light images by using an infrared filter.

이런 적층형 센서의 한 가지 우려점은 적외선이 가시광선 센서에서 노이즈로 검출되지 않을까 하는 점이다. 많은 경우, 일반적인 가시광선 센서는 적외선의 영향을 IR필터를 사용해 없애고 있다.

This time, Olympus dispelled such concerns by reconstituting visible-light images without infrared components based on signals output from the top and bottom layers, the company said.

이번 발표에서 올림푸스는 상층부와 하층부의 신호출력을 이용하여 가시광선 대역의 이미지를 재구축하여 이러한 문제점을 없앴다고 밝혔다.

상대에게 상처를 주기보다는 같이 즐거워 할 수 있는 멋진 코멘트 부탁드려요.

상대방에 대한 비방이나 욕설등 부적절한 코멘트의 경우 운영진의 판단하에 삭제될 수 있으니 주의 부탁드립니다.